Why SteamIQ Is the Smart Choice for Your Business

SteamIQ delivers real-time steam trap monitoring with AI-driven analytics, helping you reduce energy waste, prevent downtime, and optimize system performance.

With industry-first innovations like LoRaWAN connectivity and water hammer detection, our solution is built for reliability, efficiency, and long-term savings

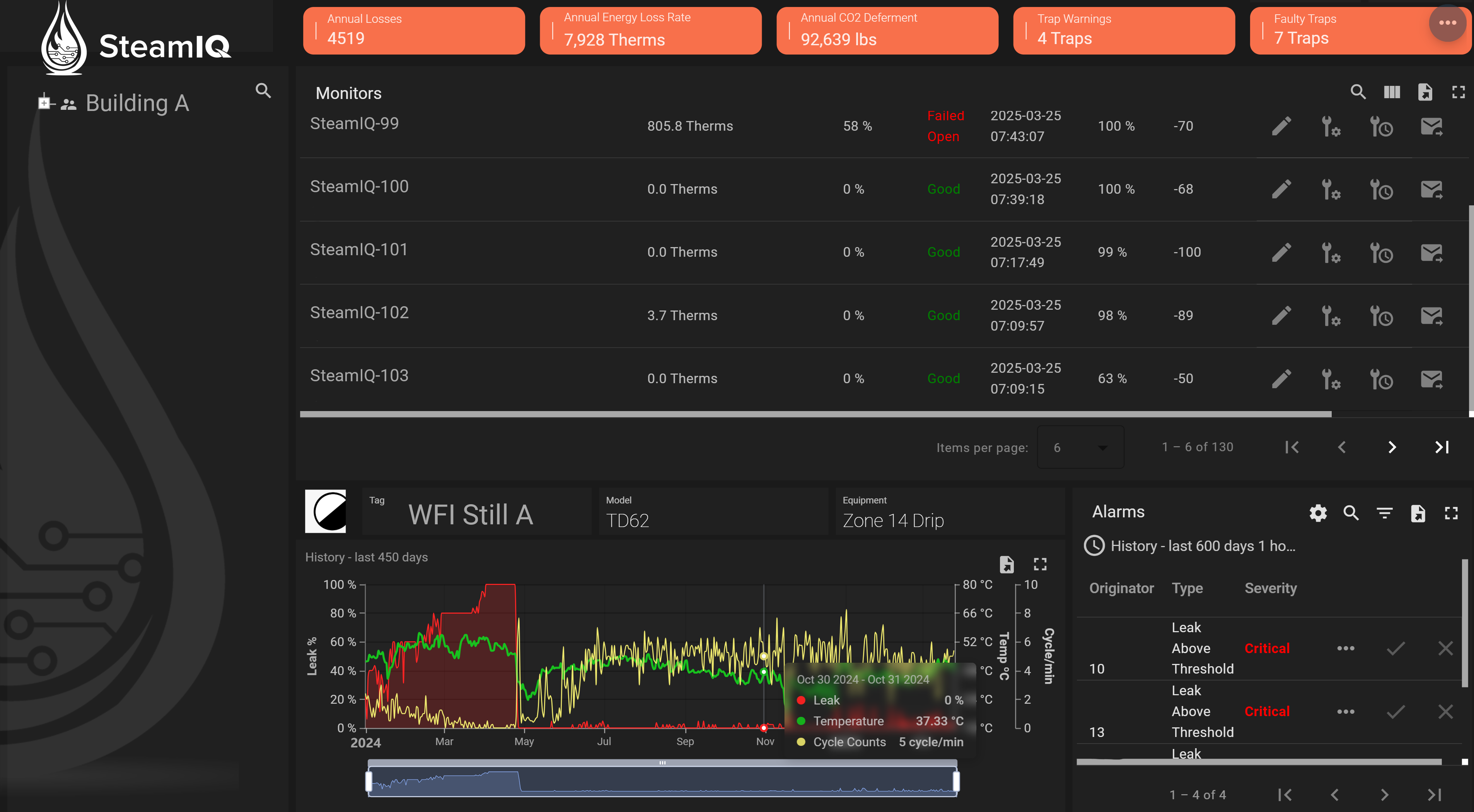

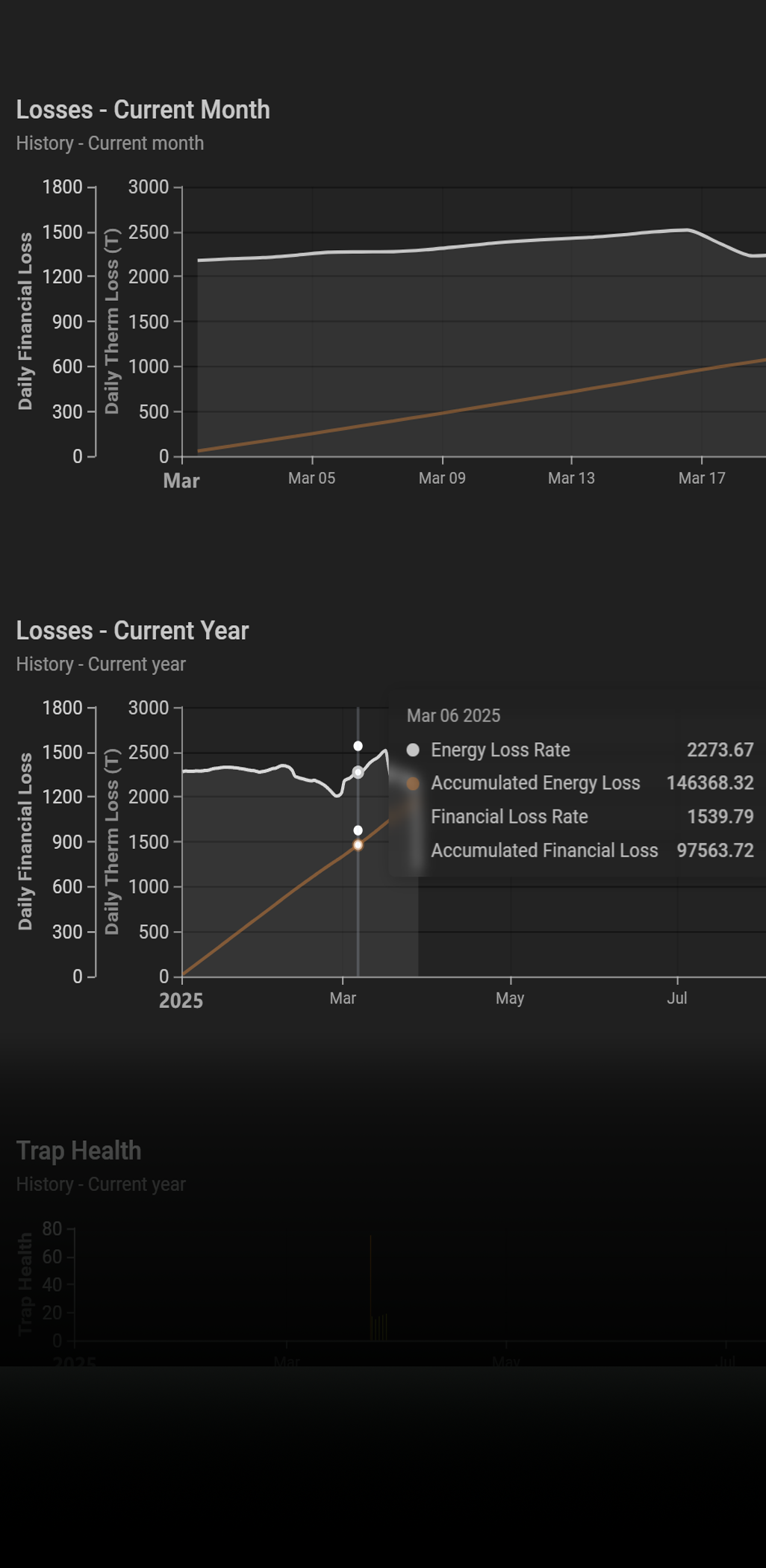

See Your Steam System Like Never Before

SteamIQ’s cloud-based dashboard brings every trap online—with real-time trap activity, calculated losses, and automated insights

Unified Dashboard

All monitored steam traps are visible in one central interface. Easily sort, search, and drill into trap performance across buildings, zones, or assets. Everything is live and fully configurable.

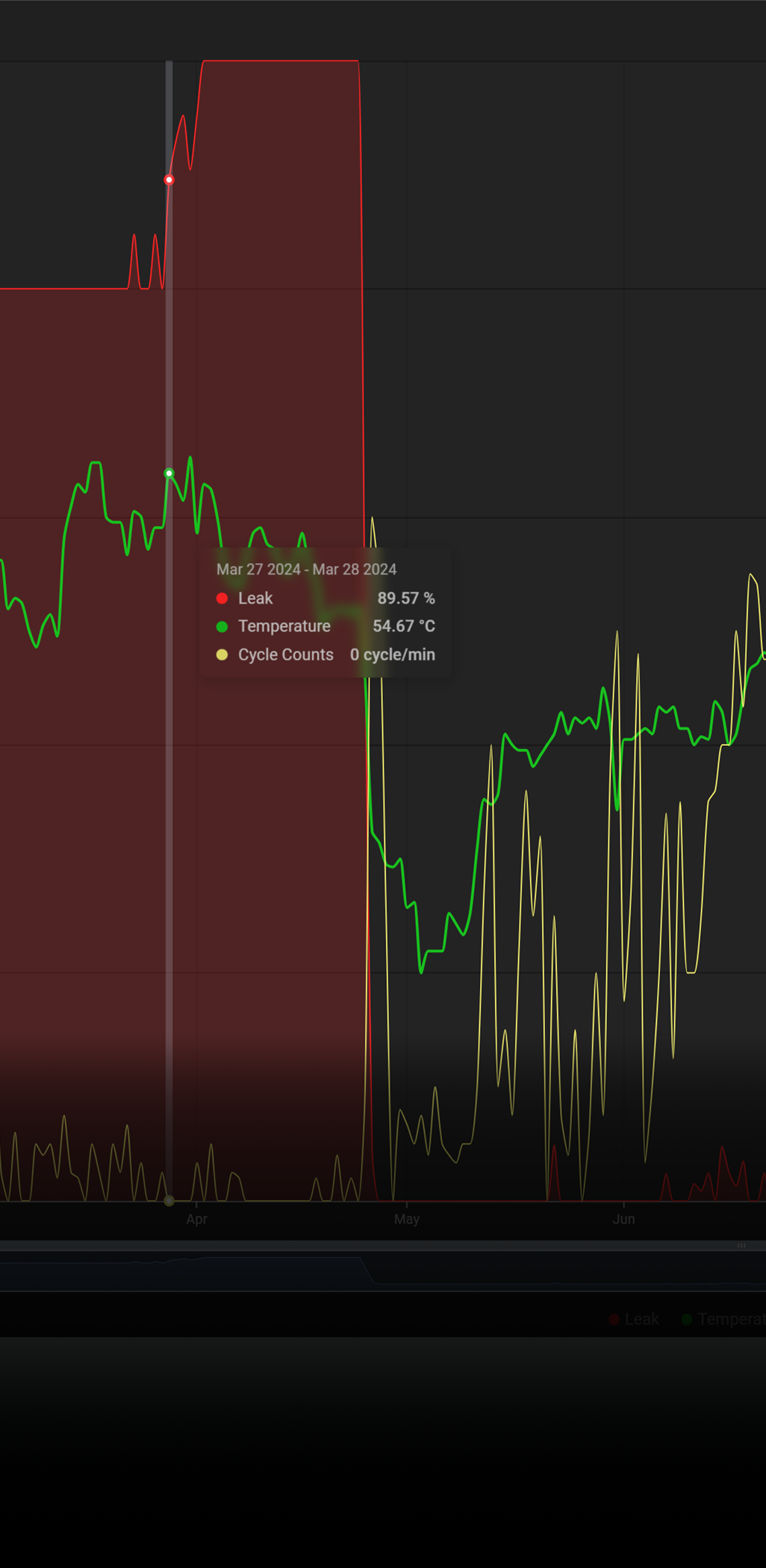

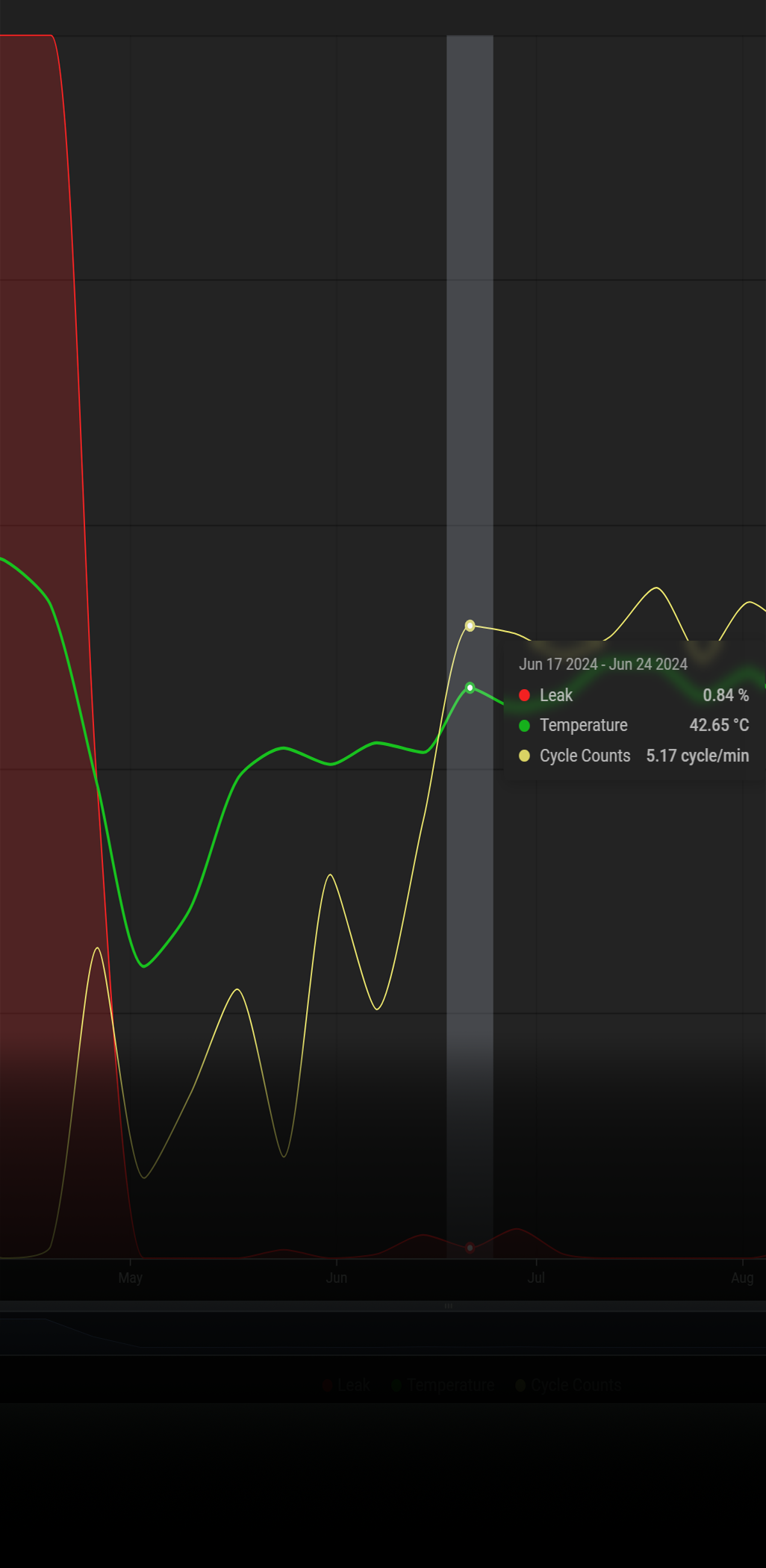

Leak Detection

Real-time ultrasonic sensing detects leaks long before they become visible or costly. Leak percentage is continuously trended, helping you catch issues early and prioritize repairs.

Cycle Counting

SteamIQ’s differential ultrasonic sensing detects whether a trap is cycling—like an EKG for your steam system. Trending this behavior over time reveals traps that are degrading, stuck, or have failed closed.

Steam Hammer

SteamIQ uses a patented ultrasonic method to detect water hammer events as they occur. By identifying where and when hammer begins, facilities can catch early warning signs and take action before costly damage occurs.

Therm Loss

Energy losses are calculated using Napier’s equation for each failed or leaking trap. Annual therm loss and CO₂ impact are quantified for easy reporting and ROI tracking.

Get a Price Quote

Request a personalized price quote tailored to your business needs